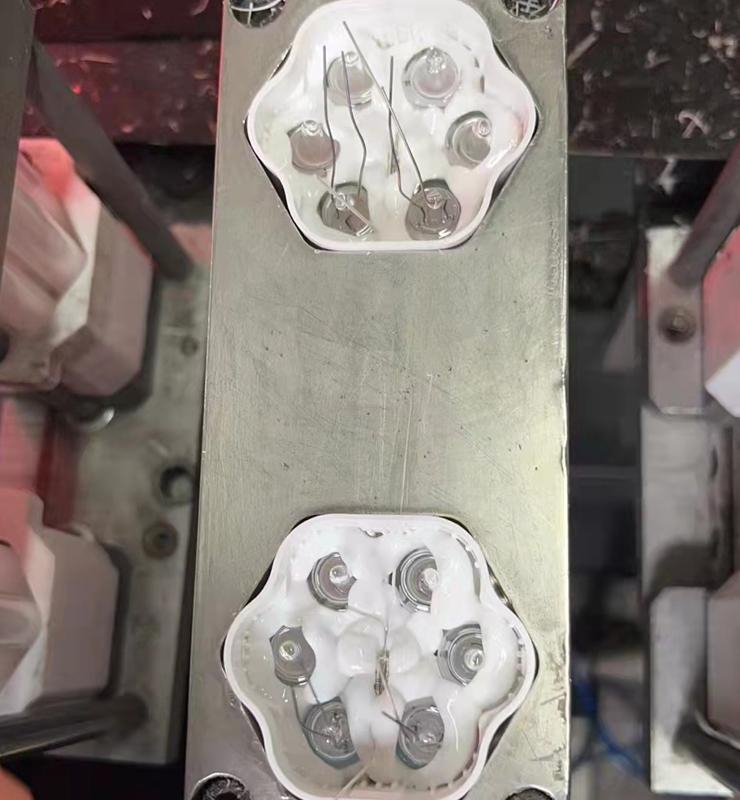

Product use: This series of energy-saving lamp glue is suitable for the bonding of energy-saving lamp plastic parts (PBT material) and lamp tubes.

technical parameter:

| Lamp glue model | 658-Ⅲ glue |

| Solid content (%) | ≥80 |

| Tensile shear force between 3U lamp tube and plastic lower cover after curing (N) | >125 |

| Viscosity (25℃, Pa.s) | 200-800 |

| -30~120℃ cold and heat shock test, one cycle per hour | >1000 |

| Heat resistance (decomposition temperature, °C) | >275 |

| Breakdown Voltage (KV) | ≥4.0 |

| Acidity and alkalinity | neutral |

| flame retardancy | incombustible |

Features:

658 series products are water-based adhesives, which are non-toxic and environmentally friendly, with high solid content, fast drying speed, strong adhesion, no cold explosion, no corrosion, moisture resistance, high temperature resistance, and good insulation after curing.

The drying and curing speed of 658-Ⅲ type energy-saving lamp glue is between 658# energy-saving lamp glue and 658-Ⅱ type energy-saving lamp glue, the performance is close to 658-Ⅱ type energy-saving lamp glue, mainly suitable for U-shaped lamps and high-power energy-saving lamps In the production of lamps, the crooked tube can be corrected after dispensing (compared with 658# energy-saving lamp glue, the baking temperature should be reduced or the baking time should be shortened before the crooked pipe correction). Production of energy-saving lamps. 658-III type energy-saving lamp glue can be completely cured after baking at 120 ℃ for 35 minutes. Slight cracking may occur during cold curing, but the tensile shear force between the lamp tube and the plastic part is still higher than the standard requirement.

Instructions:

1. Stir before use: because different users have different requirements for the fluidity of the glue when producing different types of energy-saving lamps, the 658 series energy-saving lamp glue provided by our company is relatively thick when it leaves the factory. Add water and stir to adjust the fluidity as needed. Before stirring, clean up the residual glue and sundries in the mixing tank, then pour the whole barrel of new glue into the mixing tank, and after stirring for 10 minutes, add an appropriate amount of water (300~500 ml) and continue stirring for about 20 minutes. The fluidity of the glue is controlled by the amount of water added and stirring. The more water added and the longer the stirring time, the better the fluidity of the glue, the lower the surface tension, and the better the wettability to the surface of the lamp tube and plastic parts (microscopically). It is manifested as the closer contact with the surface of the lamp tube and plastic parts). Under the premise of not leaking glue, the thinner the glue, the stronger the bonding between the lamp and the plastic part after curing. Usually, when the gap between the lamp tube and the plastic part is small, the amount of water should be appropriately added, so that the glue can automatically level and fill the gap after dispensing; when the gap between the lamp tube and the plastic part is large, add more water. The amount of water should be appropriately less, otherwise glue leakage will easily occur after dispensing. After the glue is adjusted, it should be put into use within 2 hours, and the container should be covered before use to prevent the surface from drying and crusting.

2. Dispensing: First of all, it must be ensured that there is no residual glue and debris in the dispensing machine and pipeline, and then pour the mixed glue into the dispensing machine. When dispensing, try to maximize the effective contact area of the adhesive layer with the lamp tube and plastic parts. The amount of adhesive should be uniform, and the thickness of the adhesive layer should be controlled at 6-9mm. If the amount of glue is too small (the area of glue is too small), follow-up operations or pulling the plastic parts before the glue is dry, it is easy to cause degumming. If the amount of glue is too large or uneven, it is difficult to fully dry and cure. Unused glue should be kept in a sealed bag (cover). When the glue is used for more than 2 hours, precipitation may occur after the glue is diluted, so the glue should be stirred for about 3 minutes.

3. Drying and curing: It is recommended to bake in a drying tunnel of 120~140℃ for 25~30 minutes for curing. The baking temperature can be appropriately increased on the premise that the adhesive layer does not crack and bulge. The higher the baking temperature, the shorter the curing time. . If you need to correct the crooked tube, it is best to do it before baking (or pre-bake at 50~80°C for 5~3 minutes before calibrating). It is very easy to crack the adhesive layer and eventually lead to the loosening of the lamp. When the lamp exits the drying tunnel, it is best to take the filament, not the plastic part, to avoid loosening of the lamp due to excessive temperature. The final assembly can only be carried out after the glue is completely dry, and the plastic parts should also be grasped when aging and offline, otherwise the lamp tube will easily become loose.

The above is for reference only. Due to the different production equipment and products of different manufacturers, the specific process parameters should be determined through experiments.

Fourth, storage method: non-flammable and explosive products, 5~35 ℃ indoor sealed storage, avoid direct sunlight and low temperature, the shelf life is 6 months.